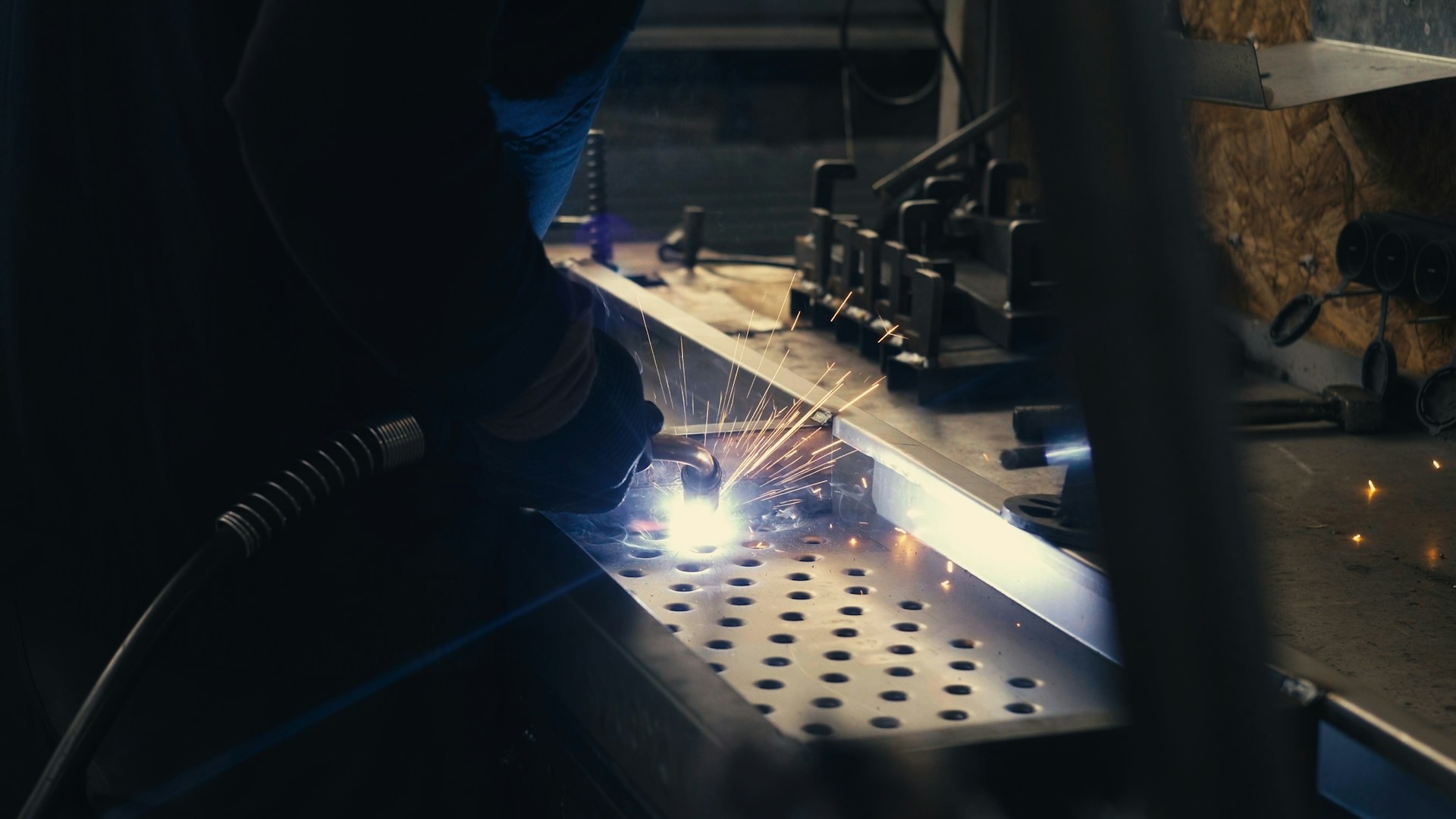

Metal manufacturing plays a central role in modern industrial processes, enabling advancements in construction, infrastructure, and countless consumer products. However, it is no secret that traditional methods in this sector have had significant environmental implications—from high energy consumption and greenhouse gas emissions to waste byproducts.

Metal manufacturing plays a central role in modern industrial processes, enabling advancements in construction, infrastructure, and countless consumer products. However, it is no secret that traditional methods in this sector have had significant environmental implications—from high energy consumption and greenhouse gas emissions to waste byproducts.

Advancing sustainability in metal production is now more crucial than ever. Enterprises are adopting eco-friendly practices to reduce their environmental impact while maintaining efficiency and profitability. Below, we explore six strategies organizations are employing to achieve more sustainable operations.

1. Reducing Energy Consumption with Advanced Technologies

Energy-intensive processes are at the core of metal manufacturing, consuming vast amounts of electricity and fossil fuels. However, emerging technologies are providing innovative ways to reduce energy consumption without compromising output.

Implementing Energy-Efficient Equipment

Advanced machinery uses less energy to produce the same volume of metals, contributing significantly to lower emissions. Many facilities are opting for equipment such as electric arc furnaces (EAFs), which are far more efficient than traditional blast furnaces.

Utilizing Renewable Energy Sources

Factories are increasingly sourcing renewable energy, such as solar or wind power, as part of their manufacturing operations. Incorporating renewable energy not only lowers their carbon footprint but also decreases reliance on volatile fossil fuel markets.

2. Recycling and Reusing Materials

One of the most impactful strategies for sustainability is closing the material loop through recycling. Recycled metals require significantly less energy to process compared to raw materials, making it a cost-effective and eco-friendly solution.

Establishing Efficient Scrap Management Systems

Recycling entails robust systems for collecting, sorting, and reprocessing scrap metal. Leading manufacturers are creating internal recycling programs that ensure minimal waste leaves their facilities.

Producing Secondary Metals

Secondary metals, derived from recycled material, are gaining prominence as a reliable and sustainable resource. For businesses reliant on metal manufacturing, using secondary metals ensures the final product retains high durability without environmental strain.

3. Minimizing Waste from Metal Manufacturing

Waste reduction is another critical component of sustainable practices. Waste products such as slag, sludge, and harmful emissions negatively affect ecosystems if not handled responsibly.

Adopting Waste-to-Energy Solutions

Some facilities incorporate waste-to-energy systems that transform byproducts into energy. For example, heat from industrial processes can be captured to power the operation itself—creating a self-sustaining cycle.

Transitioning to Clean Production Processes

By refining production lines to minimize waste generation, manufacturers can prevent excess materials from going unused or being discarded. Advances in precision manufacturing technology are leading the way in reducing waste at its source.

4. Optimizing Water Usage in Production

Water plays an indispensable role in metal production for cooling, cleansing, and processing. Yet, inefficient water usage often leads to environmental challenges such as depletion and contamination of local water sources.

Utilizing Closed-Loop Water Systems

Closed-loop systems allow manufacturers to reuse water multiple times, drastically reducing overall consumption. This approach also lowers the risk of pollution by preventing contaminated water from being discharged into surrounding ecosystems.

Water Treatment Technologies

Advanced water treatment technologies ensure that any water exiting facilities are clean and safe. Using filtration processes such as reverse osmosis, industries are taking strides in preserving water quality and reducing environmental harm.

5. Innovation in Eco-Friendly Materials

Sustainability goes beyond the production process itself—it also involves the materials being used. Organizations are focusing on the research and development of alternative, eco-friendly materials to reduce reliance on finite resources.

Lightweight Alloys and Composites

Companies are exploring alloys that are lighter and stronger than traditional metals. These innovations improve product performance while reducing material usage.

Biodegradable or Recyclable Coatings

The use of coatings can improve the durability of metal products. Opting for easy-to-recycle or biodegradable coating options further supports an environmentally conscious approach.

6. Partnering with Sustainable Suppliers

Sustainability within manufacturing is not solely dependent on internal practices—it extends to the supply chain. Partnering with suppliers committed to eco-friendly initiatives can elevate a business’s overall environmental responsibility.

Vetting Suppliers for Green Certifications

Suppliers with sustainability certifications demonstrate adherence to environmental best practices. Choosing green-certified suppliers ensures that sourcing materials align with eco-friendly goals.

Leveraging Digital Tools for Audit Transparency

Tools from MRO-PT enable businesses to access high-quality, durable parts with greater transparency, helping track environmental data and improving supply chain sustainability. Partnering with platforms prioritizing sustainability optimizes resource use while reducing environmental impact.

Making the Case for Sustainable Metal Manufacturing

Implementing these eco-friendly practices is no longer a luxury in metal manufacturing—it is a necessity. Consumers and businesses alike are demanding more transparent operations, driving industries to reduce waste, energy consumption, and environmental harm.

For organizations looking to future-proof their operations, sustainability is the key to long-term success. Adopting these practices empowers businesses to meet growing environmental regulations while achieving cost efficiencies and maintaining competitive advantages.

Explore how sustainable practices and innovative solutions can transform your enterprise for the better. Consider how these strategies can align with your values and business goals as you take the next step toward an eco-conscious future.